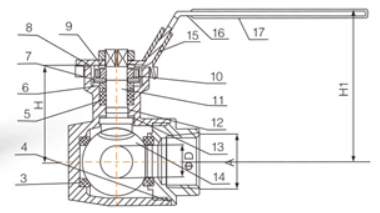

1、 Product Overview:

The threaded three-way ball valve has a compact structure, reliable sealing, simple structure, and easy maintenance. The sealing surface and spherical surface are often in a closed state, which is not easily eroded by the medium and is easy to operate and maintain. It is suitable for general working media such as water, solvents, acids, and natural gas. It is mainly used to cut off or connect media in pipelines, and can also be used for fluid regulation and control.

2、 Sealing performance:

1. The sealing ring is made of alloy steel overlay, so the hard sealed ball valve will not experience significant wear when opened or closed.

2. Good sealing performance; Due to the fact that the sealing of the hard sealed ball valve is manually ground until the valve core and sealing ring are completely aligned before use. So his sealing performance is reliable.

3. Light switch; Due to the use of a spring at the bottom of the sealing ring of the hard sealed ball valve to tightly hold the sealing ring and valve core together, the switch is very light when external forces exceed the pre tightening force of the spring.

4. Long service life: It has been widely used in various sectors such as petroleum, chemical, power generation, papermaking, atomic energy, aviation, rockets, and people's daily lives.

3、 Working principle:

Three way ball valves are divided into L-shaped and T-shaped. The L-shaped pneumatic three-way ball valve is suitable for switching the flow direction of the medium and can connect two perpendicular channels. The T-shaped pneumatic three-way ball valve is suitable for dividing, merging, or switching the flow direction of media. The T-shaped hole can connect three channels to each other or two of them. The three-way ball valve generally adopts a two seat structure, but can also adopt a four seat structure according to user requirements.

4、 Product features:

1. Compact structure, quick opening and closing, smooth flow channel, and low fluid resistance.

2. Good sealing performance: Utilizing the four sided valve seat material polytetrafluoroethylene elastic deformation to achieve leak free sealing.

3. One valve for multiple purposes: Any port can be used as an inlet without leakage, while a three-way valve can be made into either an L-shaped or T-shaped port.

4. Easy maintenance: After the system is depressurized, it can be inspected and repaired without removing the entire valve body.

* Please feel free to contact us, we will reply you within 24 hours.